Project: Digital Manufacturing Technologies for the Development of Smart Sensors and Electronics for Agro-industrial systems

Acronym

DigiMan

Duration

01/12/2017 - 30/11/2020

Network

MANUNET III

Call

Manunet Call 2017

Project summary

The DigiMan project developed innovative sensor platforms for agro-industrial applications by providing a digital manufacturing process chain based on printing technologies and nanomaterial inks. This makes it possible to miniaturize the sensors, to achieve a flexibility in the target sensor properties and to realize these sensors in economically low cost even for small sensor batch quantities.

The project utilized digital technologies for the sensors manufacturing, illustrating the benefits of a 3-D prototype philosophy (rapid, simple and cost effective). Environmentally friendly digital additive printing technologies like inkjet or aerosol-jet as well as drop-coating and laser machining made it possible to miniaturize the sensors sizes, along with a reduction in needed sensor power consumption. The applied technologies allow the customization of sensor properties and to realize this economically even for small sensor batch quantities. The equipment involved does not need expensive clean-rooms or vacuum technologies and is already introduced in the market. The software for digital design of manufacturing this sensor platforms is simple and has open access or free distribution on student level, which makes a significant contribution to the dissemination of the developed technologies and materials among future engineers by a reduced “price of entrance”.

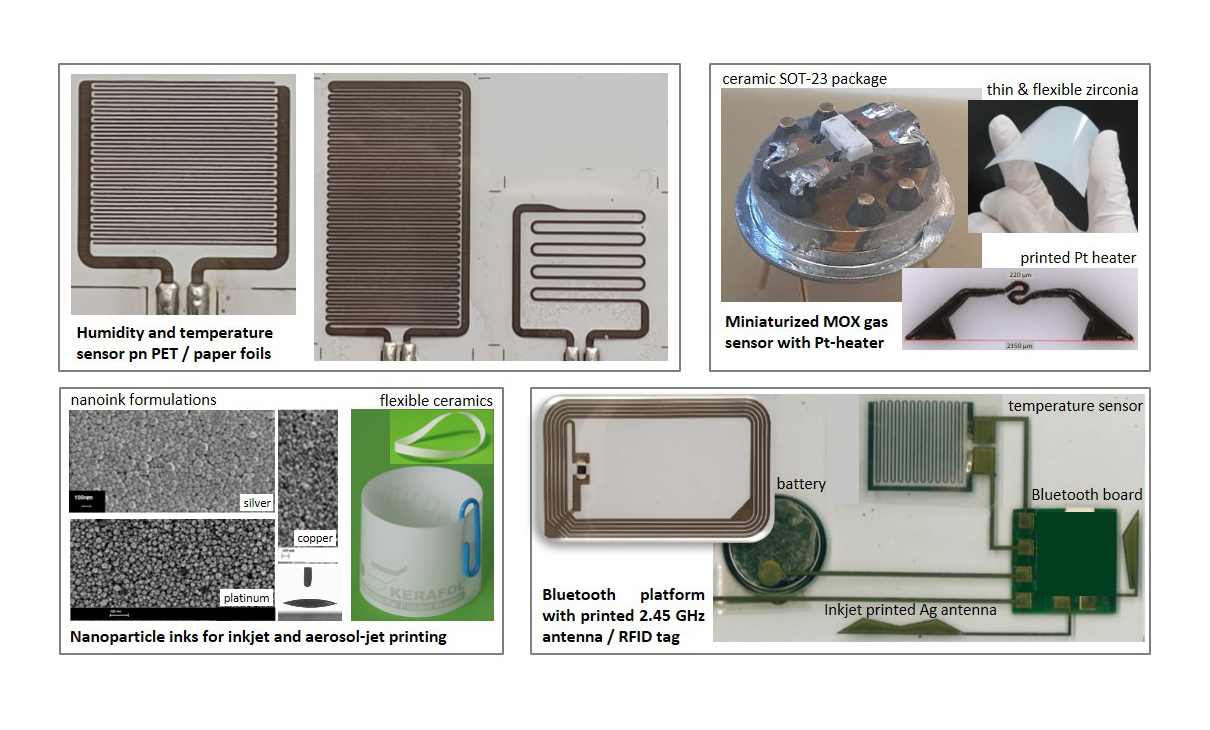

Material developments lead to the application of self-synthesized silver, copper and platinum nanoparticle inks, which are compatible to inkjet and aerosol-jet printing (particle size control < 200 nm, variation of ink solid content up to 50 wt.-%, good sedimentation stability achieved). These were used for the resource-efficient printing of miniaturized heaters, antennas for wireless data transmission and functional sensor layers to detect humidity and temperature.

The first sensor platform comprised a metal-oxide semiconductor gas sensor (MOX, ceramic MEMS) printed on a newly developed very thin (20 to 40 µm) and mechanically flexible yttria stabilized zirconia membrane. A direct printed miniaturized platinum heater (40 µm line width, up to 500 °C local temperature) led to a very low power consumption (< 200 mW), which is highly attractive for gas sensing applications. The thin zirconia membrane is compatible to laser processing and ceramic packaging technologies, which have potential to obviate some difficulties associated with traditional packaging technologies (integration of filters, printing antennas, holes for gas access to sensors). This approach can become an attractive alternative for small-scale integration of sensor components. For the gas sensing electrode, special metal oxide inks for sensing methane, hydrogen, carbon monoxide and ammonia were developed.

The second sensor platform comprised digital printed humidity (25 to 75 % RH) and temperature sensors (10 to 90 °C) on low-cost PET polymer and paper foils. The inkjet printing method was scaled from sheet-to-sheet to a roll-to-roll manufacturing (R2R). A developed low energy Bluetooth sensor platform with silver inkjet printed antenna demonstrated the wireless communication of the developed sensors within a 50 m radius. An additionally printed RFID NFC communication tag can digitally label individual sensors.

Both developed sensor platforms were tested under agro-industrial relevant parameters, especially in a wide spectrum of temperatures and humidity ranges as well as in the presence of agro-industrial gases.

Funding information

Germany

Sponsored by the Federal Ministry of Education and Research (BMBF) founding No. 02P15B520.

Israel

Sponsored by the Israel Innovation Authority.

Russia

Sponsored by the Ministry of Science and Higher Education of the Russian Federation founding No. RFMEFI58718X0054.

Project partner

| Name | Role | Country |

| C.P.C Solutions Ltd. | Partner | Israel |

| Fraunhofer IKTS and Fraunhofer ENAS | Partner | Germany |

| Kerafol Keramische Folien GmbH & Co. KG | Partner | Germany |

| RIIT Ltd. OSTEC Group | Partner | Russia |

| PV Nano Cell Ltd. | Coordinator | Israel |

| Technical University of Chemnitz | Partner | Germany |

| MEPhI | associated Partner*1 | Russia |

*1 The project cooperates with the National Research Nuclear University MEPhI (Moscow Engineering Physics Institute) in a parallel Russian project concerning gas sensor development (funding project 14.587.21.0054).

Tasks of the project partner in DigiMan project

- C.P.C. Solutions Ltd.: Sensor design, scaling of printing technology and sensor manufacturing, sensor evaluation for temperature and humidity sensor on polymer foil.

- Fraunhofer Institute for Ceramic Technologies and Systems (IKTS): Development of platinum inks for printing miniaturized heaters on thin ceramic substrates.

- Fraunhofer Institute for Electronic Nano Systems (ENAS): Development of wireless communication module based on printed antennas for sensor communication.

- Kerafol Keramische Folien GmbH & Co. KG: Development of thin ZrO2 ceramic substrates for gas sensors with ultra-low power consumption.

- RIIT Ltd. (OSTEC Group) / MEPhi: Development of miniaturized cermic MEMS gas sensor.

- PV Nano Cell Ltd.: Development and scaling of silver and copper nanoinks for inkjet and aerosoljet printing of sensor elements.

- University of Technology Chemnitz: Development of additive manufacturing technologies for digital printing, scaling up to R2R sensor production.

Project publication

- Fritsch, S. Mosch, N. Trofimenko, M. Vinnichenko, M. Kusnezoff „Platinum nanoinks for inkjet printed sensors“, Poster, Printed Electronics Europe 2019 (IDTEchEx), 11.-12.04.2019 Berlin Germany, 2019.

- Kapadia, M. Fritsch, A. Kabla, F. M. Fuchs, E. Bilbao, L. Monsalve, J. Fossati, K. Y. Mitra, A. Trul, E. Agina, S. Ponomarenko, R. R. Baumann, “The Development & Fabrication of the All Inkjet Printed Electronic Devices using Novel Functional Materials Suitable for Various Sensing Applications in the Field of Printed and Flexible Electronic”, Oral Presentation, Printing for Fabrication 2019, San Fransisco, California, USA.

- Fritsch, S. Mosch, N. Trofimenko, V. Sauchuk, M. Vinnichenko, M. Kusnezoff, N. Beshchasna, M.S. Draz „Material inks for inkjet printed biomedical sensor applications“, Oral presentation and Poster, 30th Conference of the European Society for Biomaterials (ESB), 09.-13.09.2019, Dresden, Germany.

- Samotaev, K. Oblov, A. Gorshkova, M. Fritsch, S. Mosch, M. Vinnichenko, N. Trofimenko, M. Kusnezoff, F.M. Fuchs, L. Wissmeier „Ceramic microhotplates for low power metal oxide gas sensors”, Materials Today Proceedings, Vol. 30, Part 3, pp. 448-451, 2020. DOI: doi.org/10.1016/j.matpr.2019.12.394.

- Samotaev, K. Oblov, A. Gorshkova, M. Fritsch, S. Mosch, F.M. Fuchs, L. Wissmeier, M. Vinnichenko, N. Trofimenko, M. Kusnezoff „Ceramic microhotplates for low power metal oxide gas sensors“, International Scientific Conference “Materials Science: Composites, Alloys and Materials Chemistry” (MS-CAMC), St. Petersburg Russia, 20.-21.11.2019.

- Samotaev, K. Oblov, A. Ivanova, A. Gorshkova and B. Podlepetsky, "Rapid Prototyping of MOX Gas Sensors in Form-Factor of SMD Packages," 2019 IEEE 31st International Conference on Microelectronics (MIEL), Nis, Serbia, 2019, pp. 157-160, doi: 10.1109/MIEL.2019.8889576.

- Fritsch, S. Mosch, M. Vinnichenko, N. Trofimenko, M. Kusnezoff, F.M. Fuchs, L. Wissmeier, N. Samotaev, K. Oblov “Printed Miniaturized Platinum Heater on Ultra-Thin Ceramic Membrane for MOx Gas Sensors” ECS Meeting Abstracts, Vol.MA2020-01, IMCS 03: Electrochemical and Metal Oxide Sensors, 2020. DOI: 10.1149/MA2020-01282125mtgabs.

- Fritsch, S. Mosch, M. Vinnichenko, N. Trofimenko, M. Kusnezoff, F.-M. Fuchs, L. Wissmeier and N. Samotaev, “Printed miniaturized platinum heater on ultra-thin ceramic hotplates for low power semiconductive gas sensors”, Oral presentation, LOPEC conference (digital), 23.-25.03.2021.

The project results were presented at the following business fairs:

- Printed Electronics Europe 2019 (IDTEchEx), 11.-12.04.2019 Berlin Germany

- 30th Conference of the European Society for Biomaterials (ESB), 09.-13.09.2019, Dresden Germany.

- Printing for Fabrication 2019, 29.09.-03.10.2019 San Fransisco USA.

Download: Digital Manufacturing Technologies for the Development of Smart Sensors and Electronics for Agro-industrial Systems (PDF)

Download: DigiMan - Official end report (PDF)

Project contact

PV Nano Cell Ltd.

Mrs Ayala Kabla

Fraunhofer IKTS Institute

Mr Dr. Marco Fritsch

MEPhi

Mr. Dr. Nikolay Samotaev

[contact-form-7 id="316" title="Contact form 1"]

MANUNET project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement nº 721267.

MANUNET project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement nº 721267.